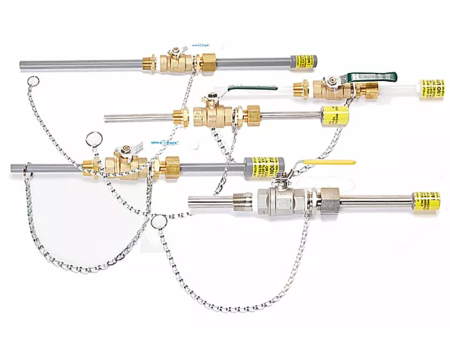

High pressure chemical injection quill, 1 2 to 1 , SS316, CPVC, Kynar, Hastelloy C276, Alloy 20, single with 1 2 FNPT Online

Description

DESCRIPTION

Standard injection quills are designed to ensure a more uniform and rapid dispersal of injected chemicals into the center stream of a process pipeline. This prevents corrosive liquids from clinging to the side of the pipe.

Injection quills are available in a variety of materials and pressure ranges. Pressure and temperature ranges are dependent on the material of construction and vary from 150 and 3000 psi and 100 °F (37 °C) and 750 °F (400 °C)

FEATURES

-

Type 316 Stainless Steel, Alloy 20, and Hastelloy C276 quills are suitable for high pressure, high temperature applications.

-

- Simple to use ½”, ¾”, or 1” MNPT male process connection and ½”, ¾”, or 1” MNPT male chemical inlet connection.

-

- The QC series of the Eddington injection quills come with a built-in check valve to prevent back flow of water or steam through the nozzle and into the chemical line.

-

- The crack pressure (amount of psi required to open the check valve) on the QC series of injection quills is 20 psi.

-

-

For applications that do no require a check valve, the QB series of the Eddington injection quills come without a check valve.

-

- All of the Eddington injection quills come with two machined flat surfaces on external portion of nozzle so a wrench can be used during installation.

-

- The QC and QB injection quills come with the telltale V notch and witness mark to ensure proper nozzle alignment with process steam for proper dispersal of injected chemical.

-

- Standard quill length is 2 3 4″ long but custom lengths up to 24″ are available. For additional lengths please add the quill length desired to the end of the Eddington part number (e.g. QCFM-316-050-18).

-

- Made in the USA

-

- Available in larger sizes, up to 3” MNPT connection, contact us to request quote ([email protected])

-

- Welded safety collar

-

- Also available CPVC, Alloy 20, Hastelloy C276, SS316

-

- Made in the USA

-

MODELS

Injection Quills with Built in Check Valves MNPT Process Connection x ½”FNPT Pump Connection

![src=]()

Injection Quills without Check Valves MNPT Process Connection x ½” FNPT Pump Connection

![src=]()

-

Type 316 Stainless Steel, Alloy 20, and Hastelloy C276 quills are suitable for high pressure, high temperature applications.

- Simple to use ½”, ¾”, or 1” MNPT male process connection and ½”, ¾”, or 1” MNPT male chemical inlet connection.

- The QC series of the Eddington injection quills come with a built-in check valve to prevent back flow of water or steam through the nozzle and into the chemical line.

- The crack pressure (amount of psi required to open the check valve) on the QC series of injection quills is 20 psi.

- For applications that do no require a check valve, the QB series of the Eddington injection quills come without a check valve.

- All of the Eddington injection quills come with two machined flat surfaces on external portion of nozzle so a wrench can be used during installation.

- The QC and QB injection quills come with the telltale V notch and witness mark to ensure proper nozzle alignment with process steam for proper dispersal of injected chemical.

- Standard quill length is 2 3 4″ long but custom lengths up to 24″ are available. For additional lengths please add the quill length desired to the end of the Eddington part number (e.g. QCFM-316-050-18).

- Made in the USA

- Available in larger sizes, up to 3” MNPT connection, contact us to request quote ([email protected])

- Welded safety collar

- Also available CPVC, Alloy 20, Hastelloy C276, SS316

- Made in the USA

-

MODELS

Injection Quills with Built in Check Valves MNPT Process Connection x ½”FNPT Pump Connection

Injection Quills without Check Valves MNPT Process Connection x ½” FNPT Pump Connection

Additional Information

| Process Connection Size | 1/2", 3/4", 1" |

|---|---|

| Material | SS316, CPVC, Kynar, Alloy 20, Hastelloy C276 |

| Check Valve | YES, NO |